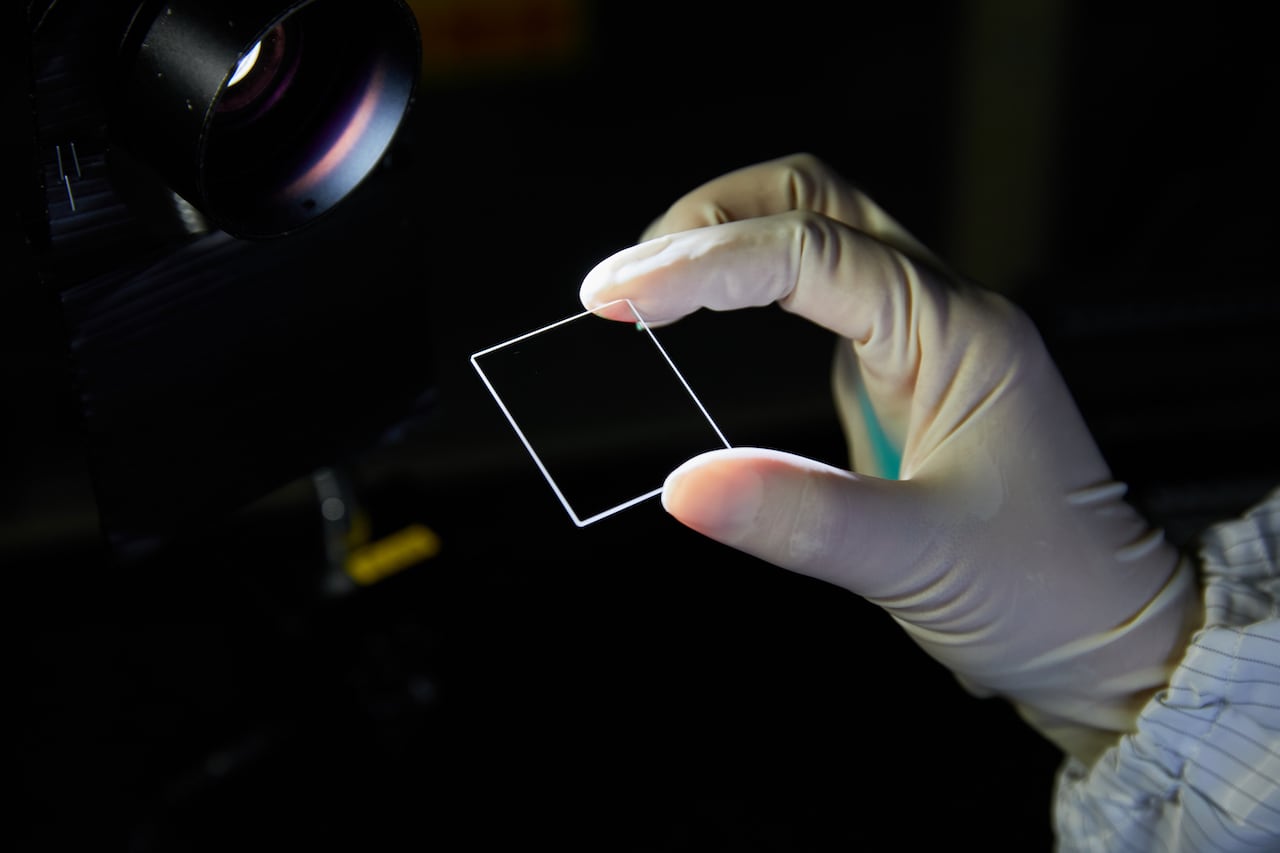

High quality thin film production technology

In order to respond to requests of special optics technology, the designed thin film must be layered correctly on the base material.

For that, we utilize materials according to the respective purposes, select filming substances and prepare several production methods.

We can handle not only the usual executable wavelength area, but also a large area from ultraviolet rays to infrared rays.

Optical technology is one of the most attention technologies today, embodying the ideals of the future.

We believe that Tokai's technology can assist your development business.

A complete production line

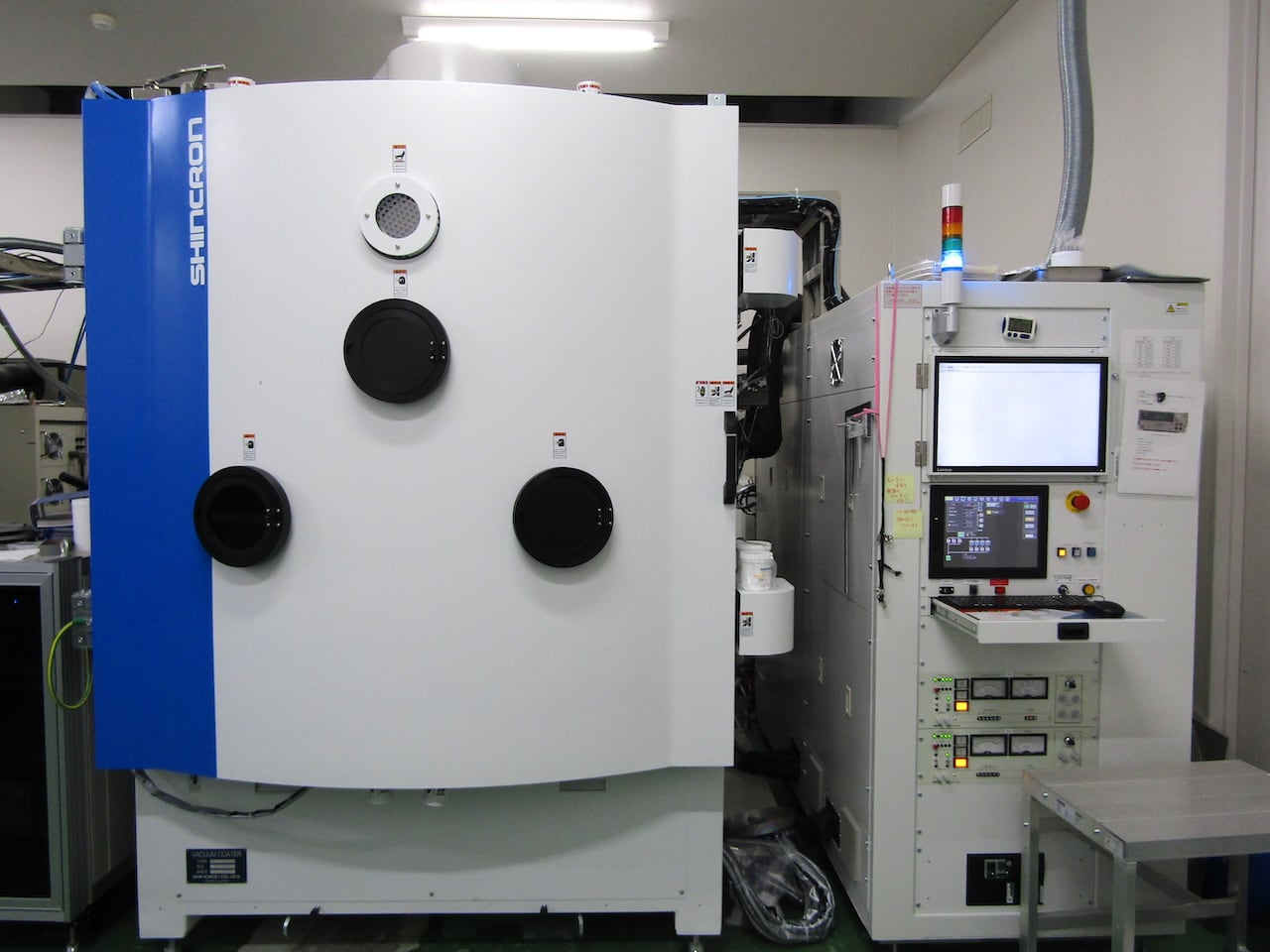

Based on the continuous improvement of quality, technology and productivity , we have introduced the newest equipment and technology, with our production line.

We provide total support, from prototyping and product development to mass production, according to customer requests and circumstances

Electron beam (EB), which heats and evaporates multiple evaporation sources individually with an electron beam, ion-assisted (IAD), which enables film formation with high density and high adhesion without wavelength shift, and low-temperature film formation with no wavelength shift. We carry out cutting-edge thin film processing by making full use of equipment such as sputtering that can obtain high-quality optical thin films.

In addition to the coating room, we have constructed a clean room under the environment of the production process to prepare the environment.

With the aim of improving quality, technology and productivity, we have introduced the latest equipment and technology to form a production line.

We provide total support, from prototyping and product development to mass production, according to customer requests and circumstances

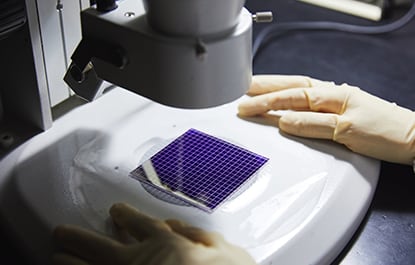

A quality control system

Thorough our quality control is what we put a lot of effort into in order to stably supply products that meet the needs of our customers and earn their trust.

In order to ensure the quality and functions after film formation, we have accumulated know-how from inspection to various measurements, and we conduct quality control according to the standards set based on ISO9001.

We have received orders from customers in a wide range of genres and have delivered high value-added and competitive products in any era.

and we have been highly praised by many industries for our quality standards and our multiple and various processed products, as well as many delivery results stand as actual proofs.

Tokai's strength is its ability to provide "high quality" products.

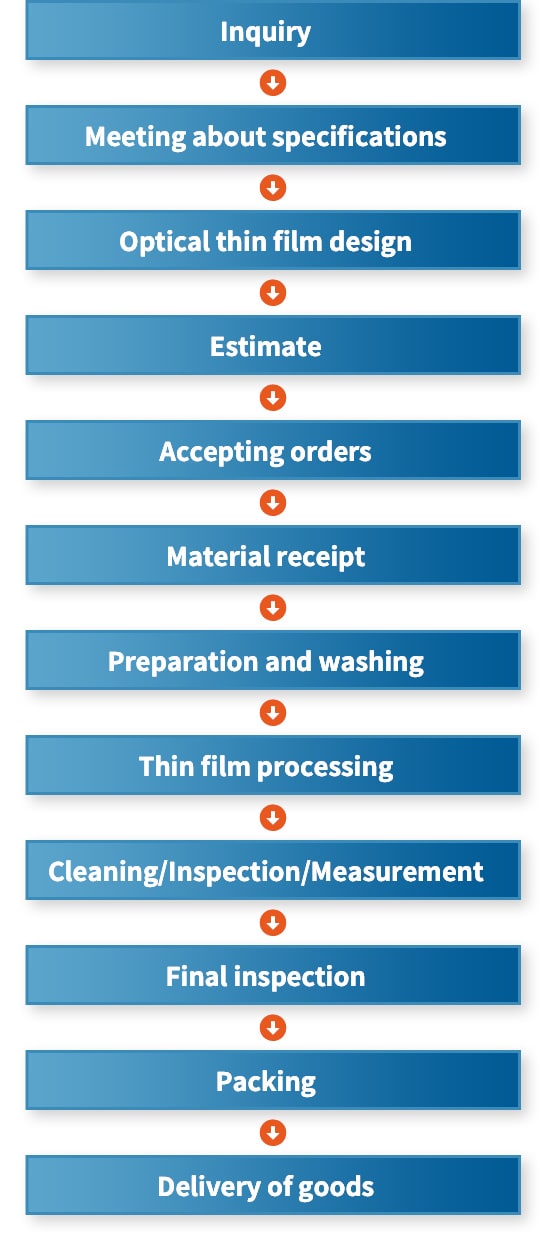

Flow until delivery

Incidental process

Regarding business consignment and services other than thin film processing, Tokai Co., Ltd. is a thin film processing manufacturer,

but we also accept the following incidental work alone or integrated work.

- Sale of monitor glasses

- Consignment of washing work

- Procurement of glass materials

- Photolithographic processing

- Consignment of measurement

- Polishing

- Detachment of joined products

- Consignment of Inspection

- Glass cutting

※Please feel free to contact us for more information

Possessed equipment

Coating equipment

We are fully equipped with a large number of vacuum deposition equipment, and perform high-precision, high-value-added coating using IAD (ion assist), SP (sputtering).

| Ion-assisted vapor deposition equipment/sputtering equipment |

|---|

Photolithography process

Equipped with exposure equipment, we can achieve high-precision patterning deposition in μm units.

| Spin Coater/Mask Alignment System/Industrial Inspection Microscope |

|---|

Clean Room

In addition to the coating room, we have constructed a clean room under the environment of the production process and have established a production system.

| Coating room | Class10000 | 3 rooms |

|---|---|---|

| Clean room | Class1000 | 3 rooms |

| Clean bench | Class100 | 15 units |

| Clean shelf | Class100 | 10 units |

| Photolithography room | ISO Class1 | 1 room |

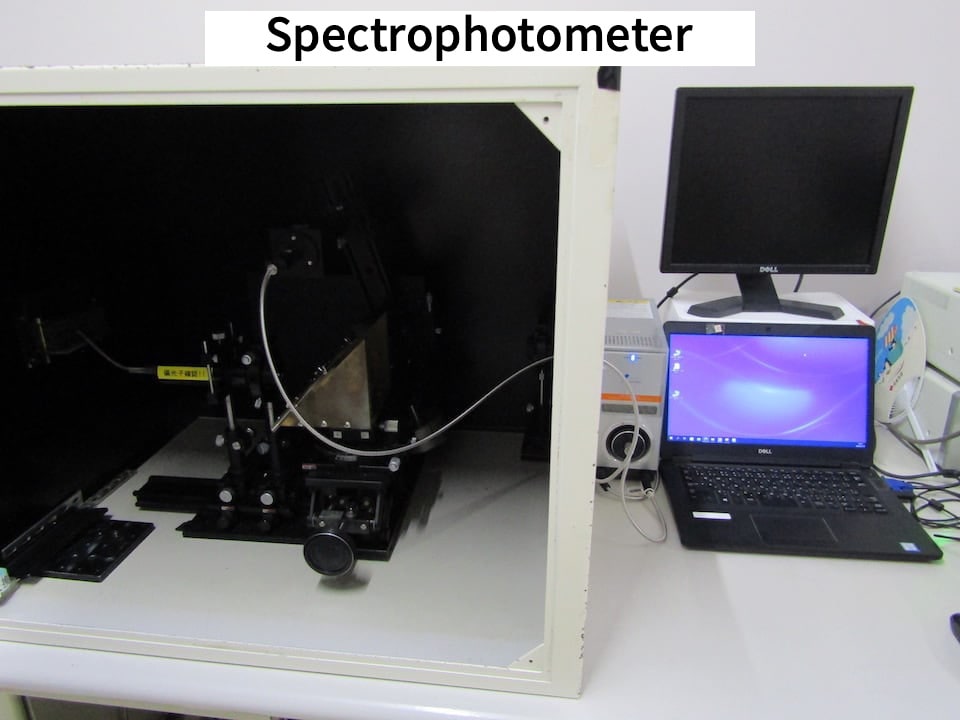

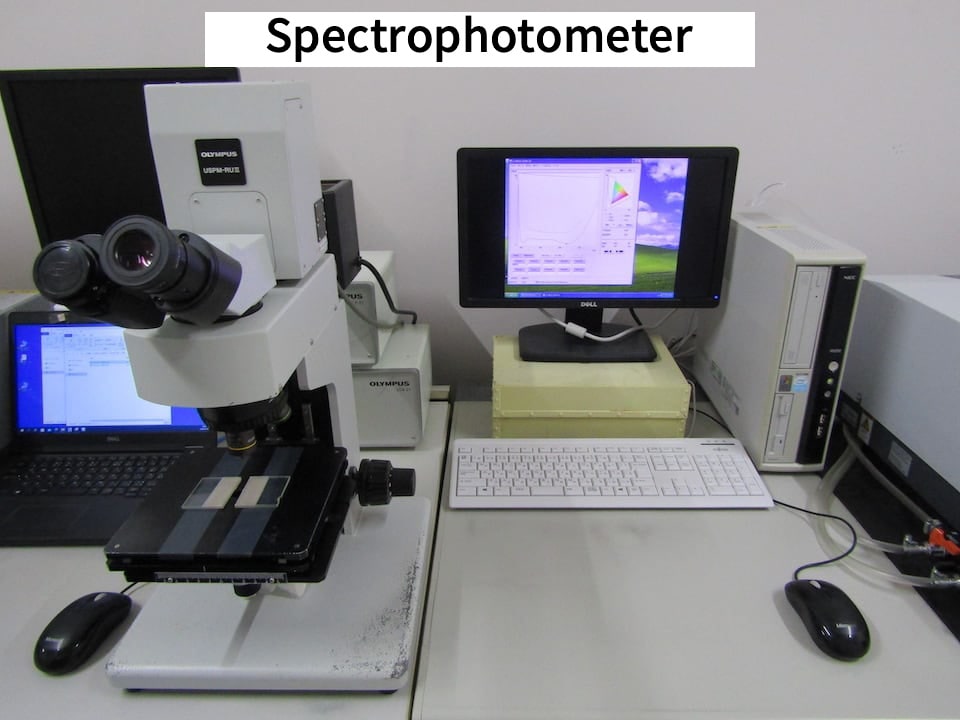

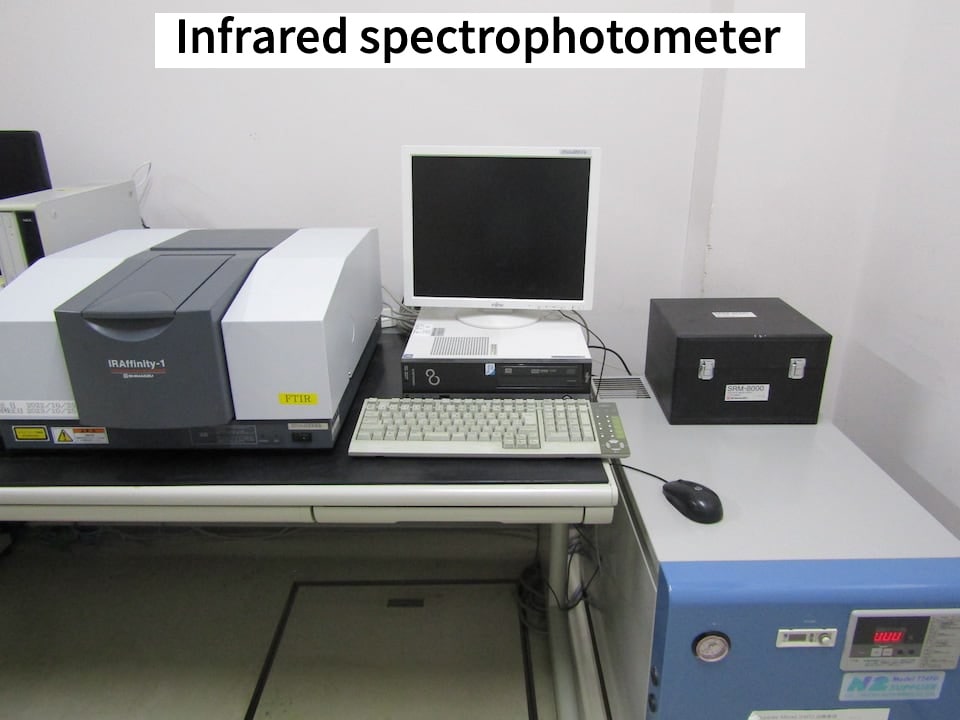

Quality Assurance System

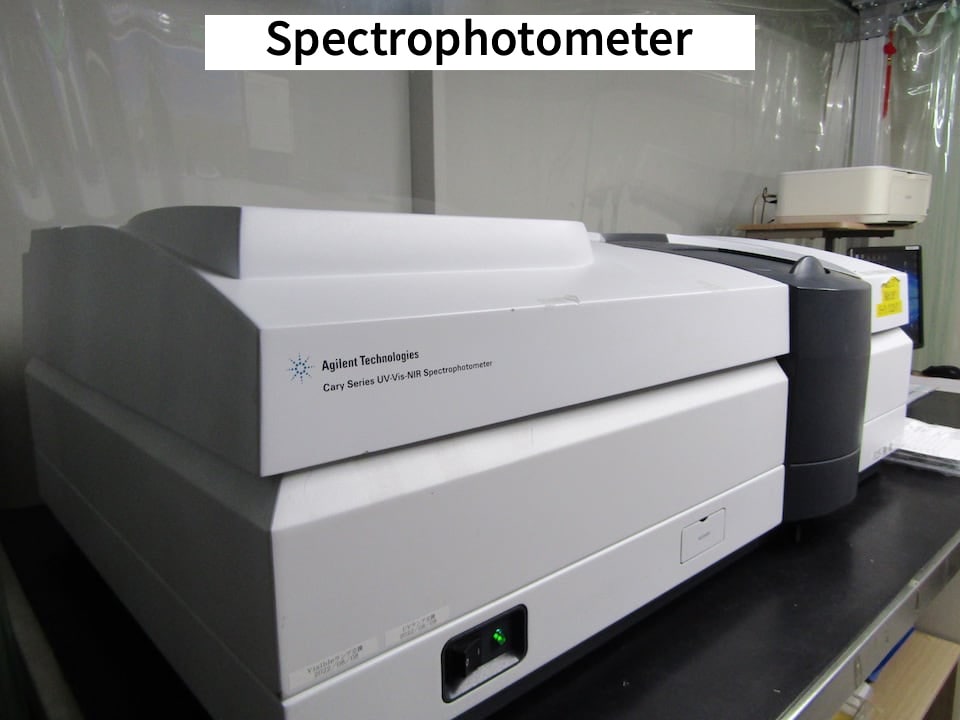

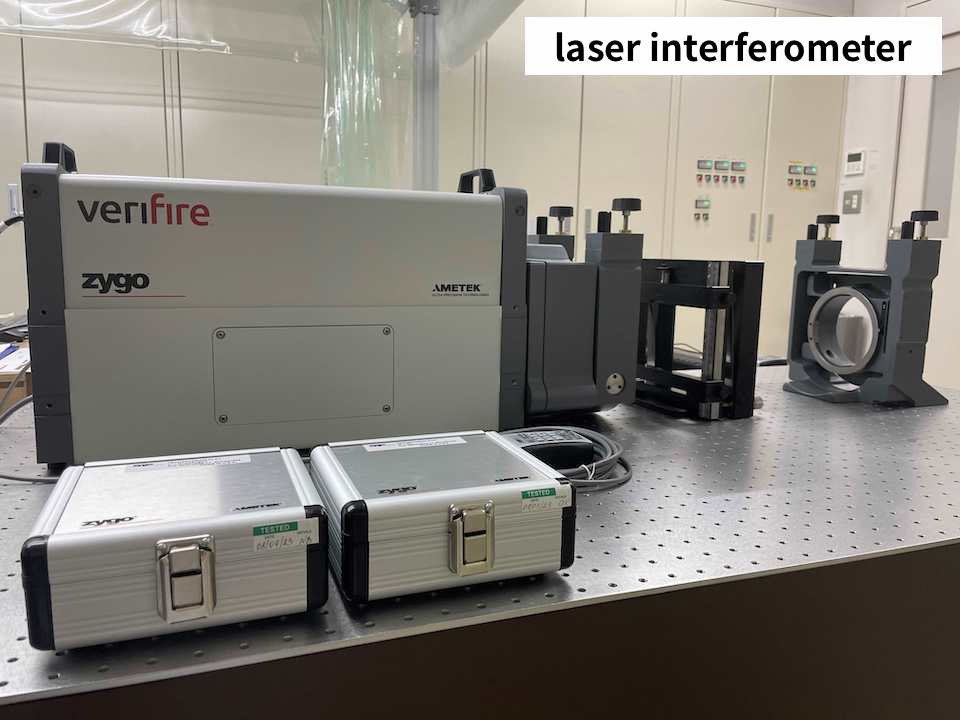

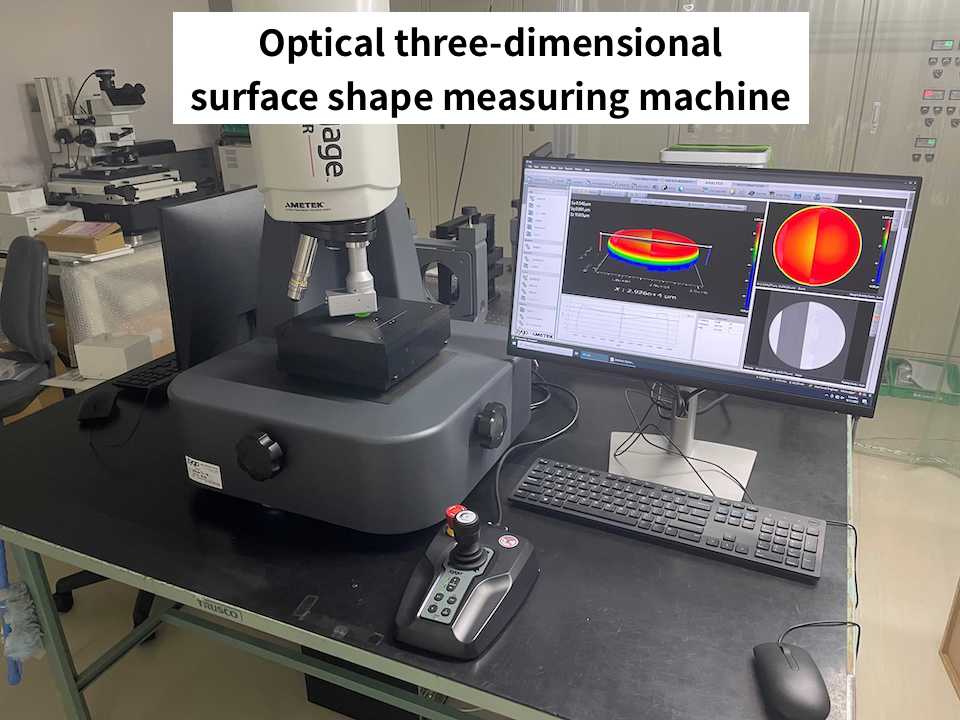

We use high-precision measuring instruments to measure and analyze products, and strive to improve quality and reliability.

We respond to our customers' demands according

to their request regarding development,

processing speed and quality based on the

three factors that promote business operations.

Business overview

Tokai has been entirely devoted itself to the optical thin film processing since its establishment.

Nowadays, with the optical technology attracting attention we are even more eager in performing our business operations.

We respond to our customers' demands according to their request regarding development, processing speed and quality based on the three factors that promote business operations.