Pattern deposition (Photolithography process)

Precision patterning can be achieved using photoresist and lift-off or etching. Feature sizes down to 3 µm can be achieved, depending on the type of coating required.

Furthermore, depending on the conditions, a size of 1 μm is also possible.

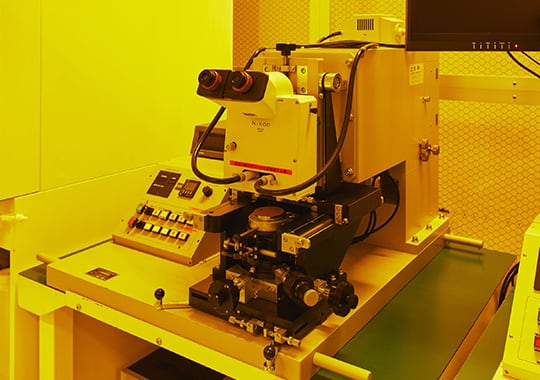

①Work environment/Equipment

We will manufacture filters/mirrors with high-precision patterns in combination with various deposition technologies.

Super clean room ISO class 1

Super clean room ISO class 1

[Process Flow] *Equipment introduction

Maximum supported size: Φ6in / Maximum substrate thickness: 25mm (Include prism)

1)Spin coater

1)Spin coater 2)Mask aligner

2)Mask aligner 3)developing

3)developing 4)Inspection

4)Inspection

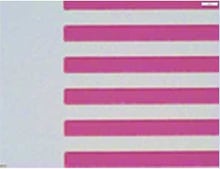

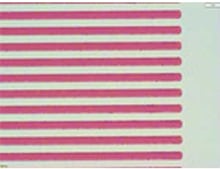

②Pattern accuracy (Dichroic film L/S)

Accuracy up to L/S = 1 μm is possible

50μm

50μm 10μm

10μm 5μm

5μm 2μm

2μm 1μm

1μm

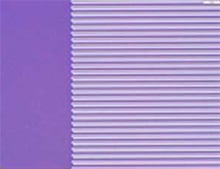

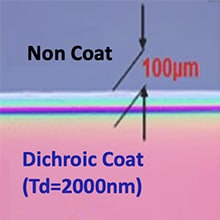

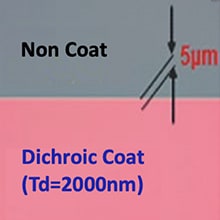

③Boundary accuracy (A faint outline)

Comparison with metal mask (our comparison)

Metal mask product

Metal mask product Photolithographic product

Photolithographic product

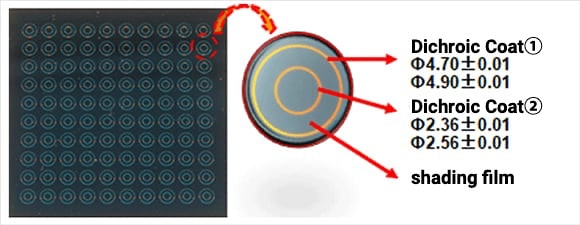

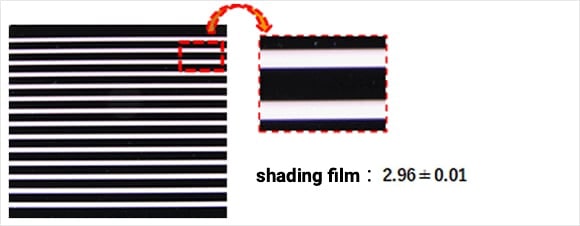

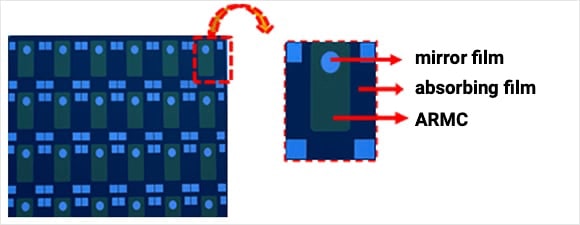

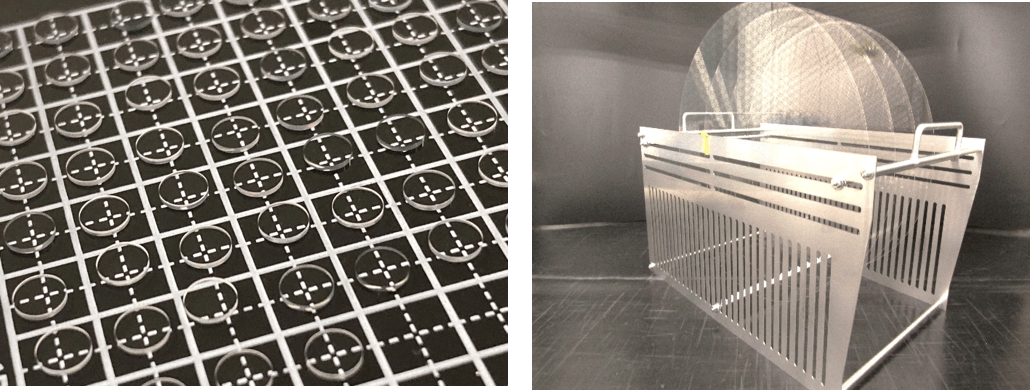

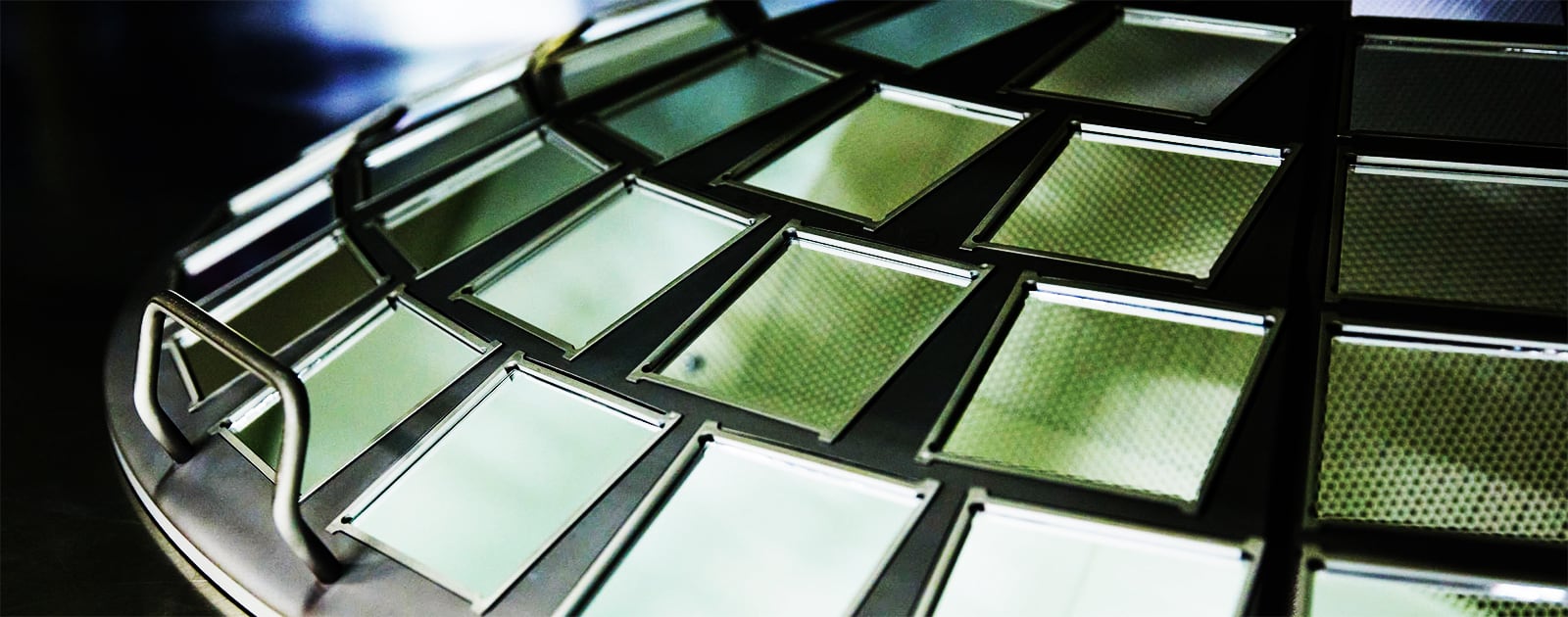

④Pattern example

1)Dichroic coat/shading film

1)Dichroic coat/shading film 2)ARMC/shading film

2)ARMC/shading film 3)Mirror film/Absorbing film/ARMC

3)Mirror film/Absorbing film/ARMC

Cleaning process

1.About precision cleaning

-

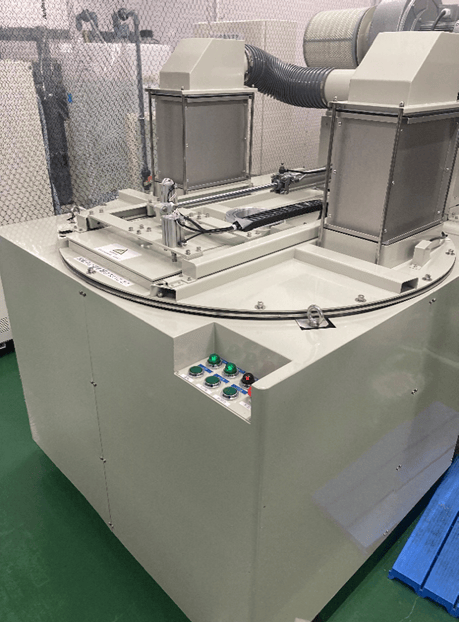

Our company has cleaning equipment equipped with high-performance ultrasonic equipment.

We also accept requests for precision cleaning processes for various glass materials.

~What is precision cleaning?~ A process in which deposits on the surface of parts are cleaned using DI water and ultrasonic waves. We have cleaning agents, DI water tank, IPA tank, vaper drying tank, centrifugal drying tank.

-

-

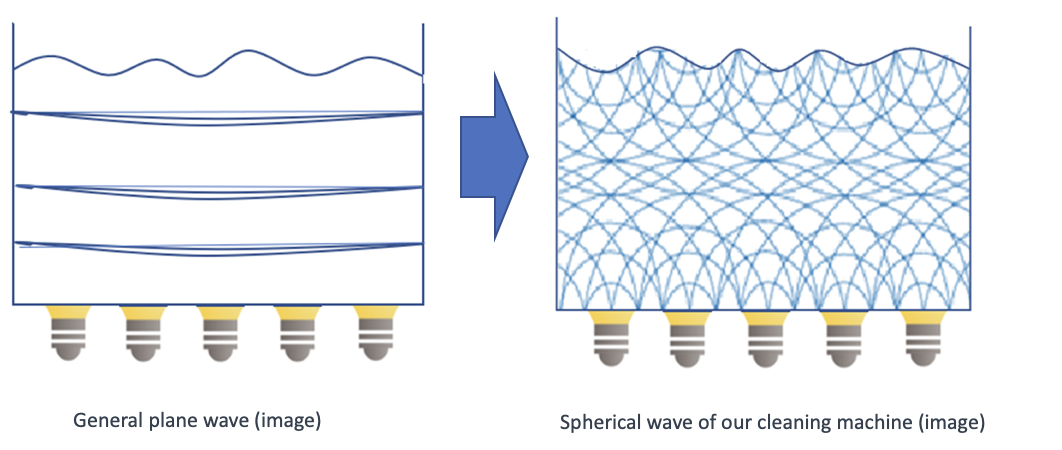

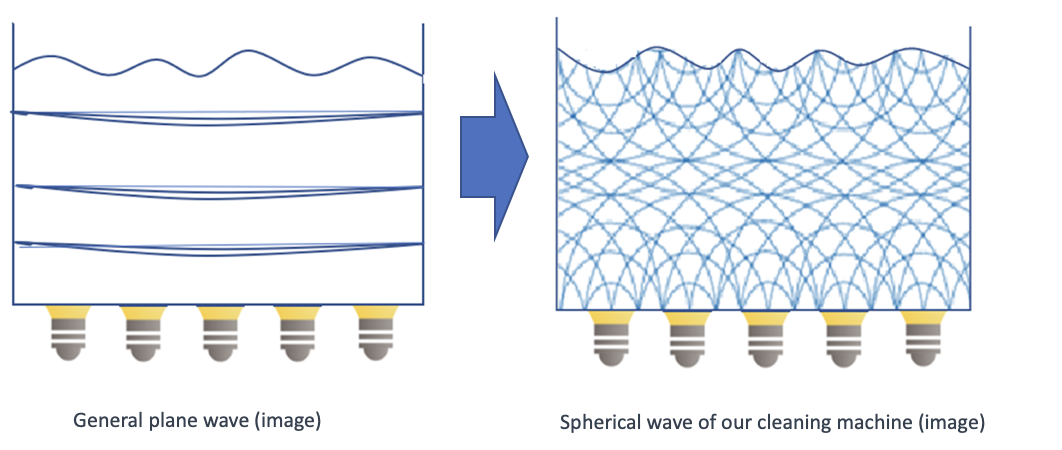

Adopts spherical wave ultrasonic transmitter Equipped with an ultrasonic transmitter that uses spherical waves that do not easily scratch glass.

Spherical wave vibration spreads powerful ultrasonic waves evenly within the cleaning tank, preventing uneven cleaning.

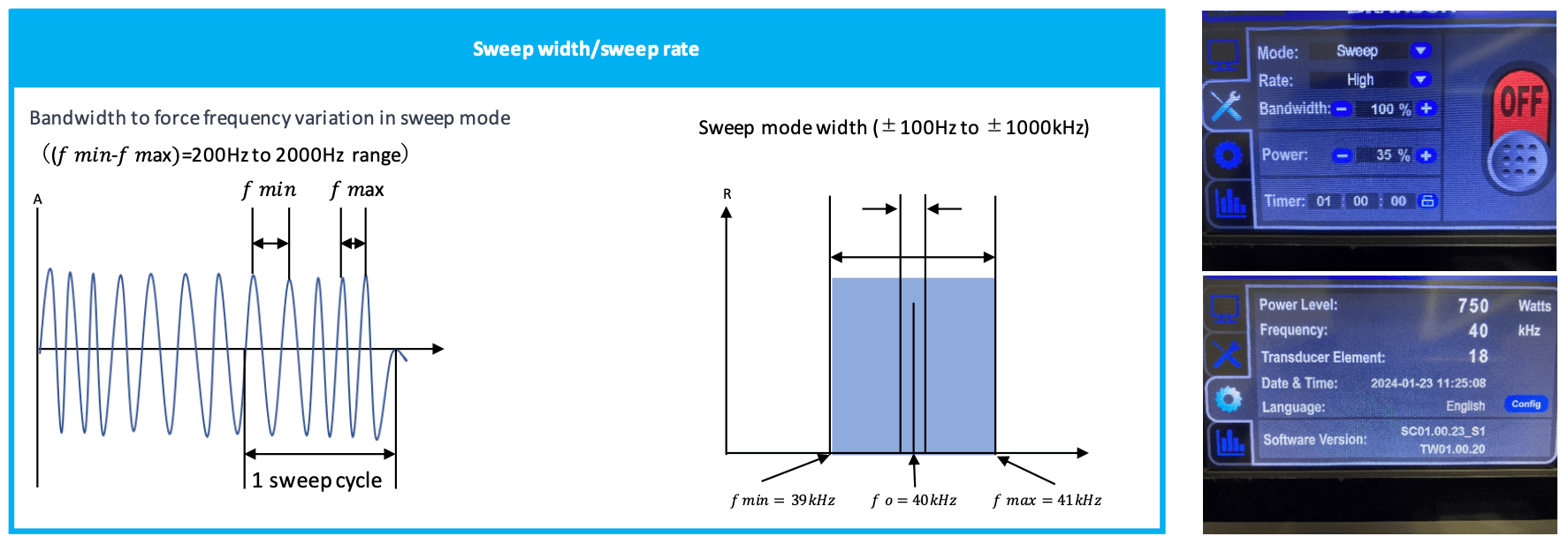

It is also equipped with a sweep function that changes the frequency within a range of ±1kHz.

The sweep feature creates a random wavelength pattern that improves energy distribution and cleaning performance for better cleaning. -

-

By using the sweep mode, the operating frequency of the ultrasonic transmitter can be varied within a fixed range.

In sweep mode, the operating frequency changes over a ±1kHz range, resulting in a more uniform cleaning effect.

-

Cleaning for soft glass materials Up until now, cleaning of soft glass materials was generally done by hand wiping with a solvent, but our high-performance ultrasonic equipment has made cleaning possible.

Please feel free to contact us for any glass cleaning needs, from general glass materials to high-wear soft glass materials such as CaF2 and FPL51. -

-

Cleaning of small to large diameter substrates This large-capacity cleaning tank can clean substrates of various sizes, from small-diameter substrates (φ3.5~) to large-diameter substrates (approx. φ300).

Other irregularly shaped boards are also available, so please feel free to contact us . -

-

-

Cleaning of resin substrates, etc. In addition to the IPA vapor drying tank, we also have a centrifugal drying tank (spin drying).

It can also clean substrates (resin substrates, etc.) that are sensitive to heat and cannot be passed through a vapor drying tank.

In addition, the pure water used in our cleaning machines is "ultra pure water" which has a higher purity than regular pure water (specific resistance value 18.2MΩ).

*The specific resistance value of pure water is about 0.2 to 10MΩ

Cleaning is performed using water with impurities reduced to the bare minimum, providing higher cleaning quality than conventional equipment.

In addition to coating, we also accept requests for precision cleaning only, so please feel free to contact us.

-

2.Other cleaning information

Our company takes on the challenge of removing various stains by applying technology to remove various stains from the jigs and tools.

Removes dirt from metal, glass, and plastic. Example: Removing abrasive material stuck to jigs and tools

-

3. Suggestion of cleaning method

In collaboration with the cleaning agent manufacturers we use, we will propose cleaning agents that include cleaning conditions suitable for glass materials.

Handling: Optical discoloration remover/optical cleaner/alkaline remover