Metal sputter film

Substrate size, Film forming material, and features that can be deposited

- W160×L325×H110(mm) *Maximum effective area for Al+SiOx film.

- Since there is very little heat damage to the workpiece, it can be uniformly and firmly applied to resins such as PC, PET, PBT, ABS, PMMA, COP, COC, glass, metal, silicon wafers, three-dimensional objects, and lenses.

- Al, Ag, Cr, NbO, Ti, Au, Cu, Pt, Pd, Rh, Ru, W, Ge, Hf, Ta, Mg, Mo, Si, Sn, Zn, Zr, Ni, Fe, etc. typically becomes a metal film

- Typical oxide film forming material include NbOX, TiOX, Al2O3, HfO2, Ta2O5, SiO2, and ZrO2.

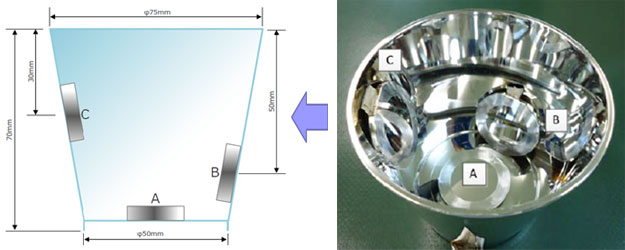

Quality evaluation

| A | B | C | |

| reflectance:450nm | 89.2 | 88.0 | 88.8 |

| reflectance:700nm | 89.24 | 87.9 | 88.1 |

| KOH test(※) | ○ | ○ | ○ |

※Base material:PC

※Al (sputtering) + SiOx (polymerization)

【Point】

Even if in the film formation with such an arrangement, there is almost no difference in the spectroscopic standard (reflectance) between individual pieces, and it is possible to form a film with a stable film thickness.

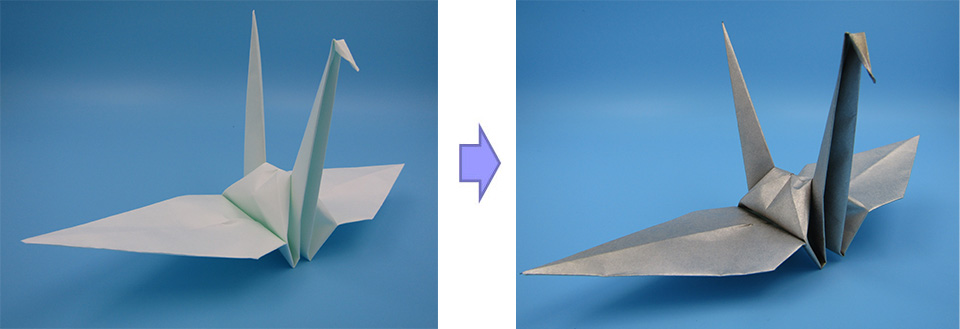

Example of metal sputtering film formation

Aluminum film deposition on paper

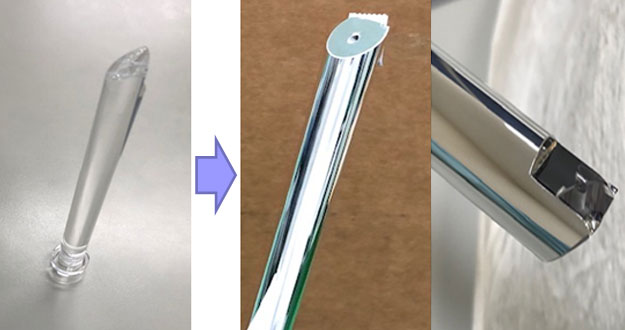

AL film formation on the filter frame

AL mirror deposition on the various shaped glass (outer periphery)

AL film formation on the resin tweezers

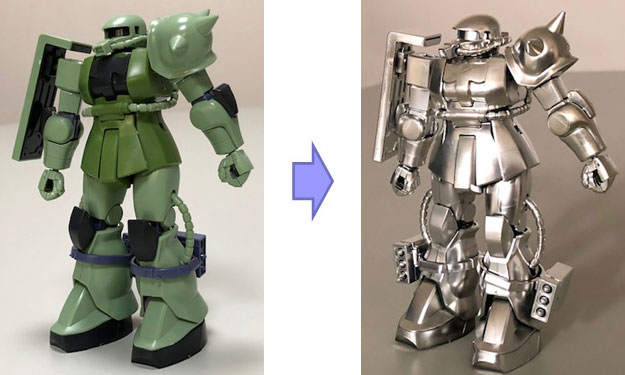

AL film deposition on the Gundam series Zaku

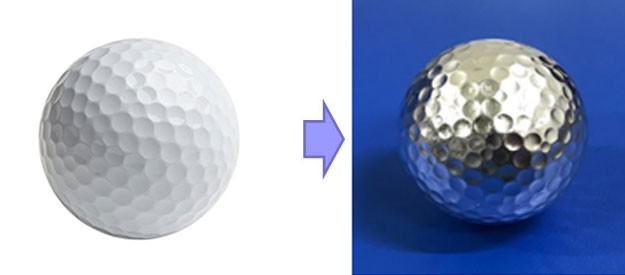

AL film formation on the golf balls

【Point】

It is possible to form a uniform, dense, and strong film even on such three-dimensional objects.

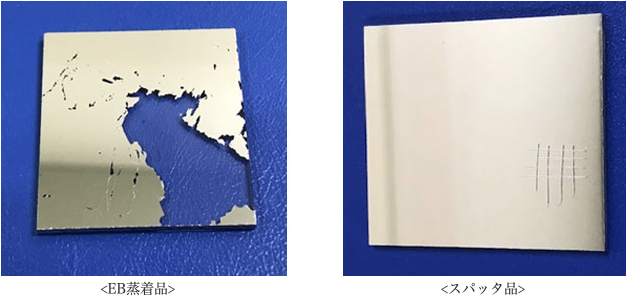

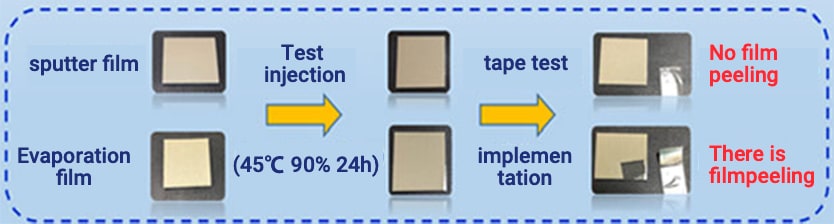

Metal film (1) Al film formation on resin substrate

In general, vapor deposition on acrylic substrates requires a hard coat (pretreatment) because there is a problem with adhesion. membrane is possible.

In addition, the deposition time is shorter than usual, resulting in high productivity and excellent spectral characteristics (reproducibility).

- EB deposition product: The film peels off at the first tape test.

- Sputtering product: No peeling of the film even after several tens of tape tests.

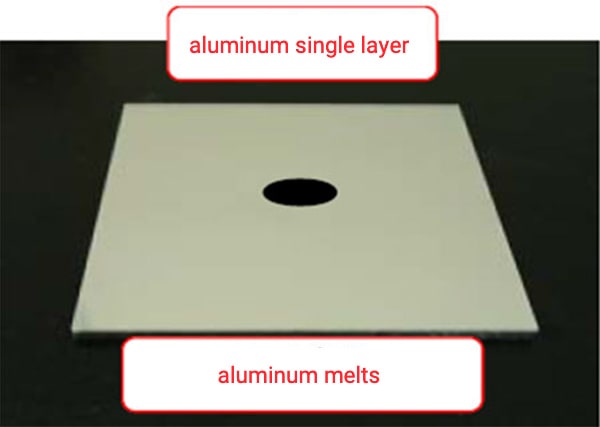

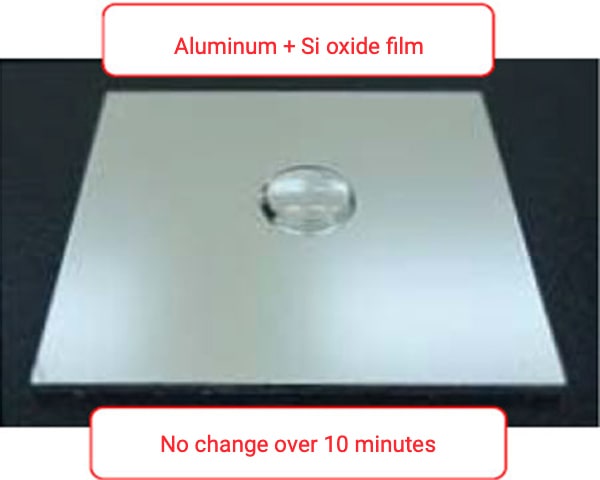

Metal film (2) SiOx film

【Point①】

After dropping 1% potassium hydroxide solution on the Si oxide film, it was confirmed that there was no corrosion on the aluminum for 10 minutes.

It has high barrier properties.

【Point②】

Aluminum corrosion prevention effect can be obtained by forming a Si oxide film by CVD.

【Point③】

The above performance can be stably maintained even during mass production.

*Documents provided by vapor deposition machine manufacturers

【Point①】

After dropping 1% potassium hydroxide solution on the Si oxide film, it was confirmed that there was no corrosion on the aluminum for 10 minutes.

It has high barrier properties.

【Point②】

Aluminum corrosion prevention effect can be obtained by forming a Si oxide film by CVD.

【Point③】

The above performance can be stably maintained even during mass production.

*Documents provided by vapor deposition machine manufacturers

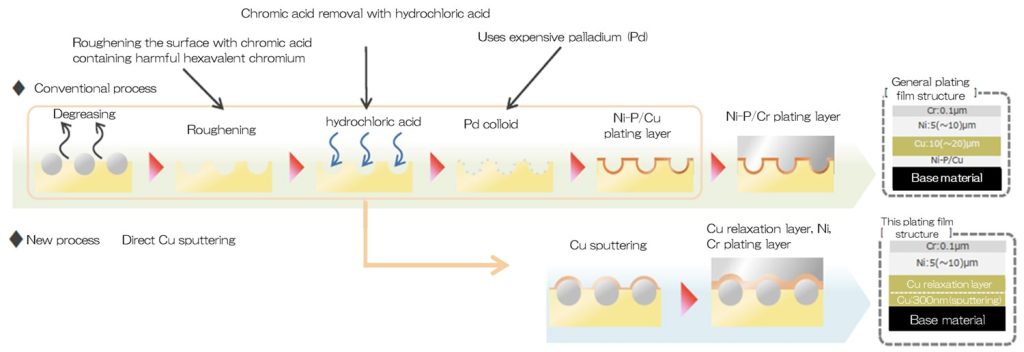

Metal film (3) Plating seed layer drying

In the electroless plating process, our unique plasma treatment and Cu film formation technology <

Expands the possibilities of plating on engineering plastics/super engineering plastics other than ABS./p>

① Reduced environmental impact by being free of chromic acid.

② Cost reduction due to metal catalyst (Pd colloid) free.

③ Good adherence to 3D shapes.

④ Achieved a peel strength of 15 N/cm (1.6 kgf/cm). (For our standard ABS sample product)

⑤ Possibility of plating on engineering plastics/super engineering plastics other than ABS.

*Documents provided by vapor deposition machine manufacturers

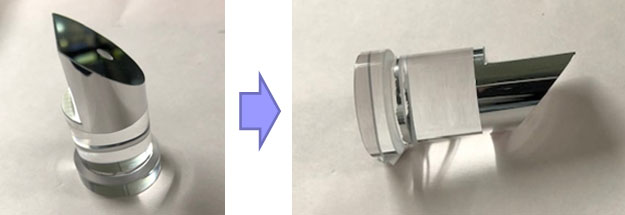

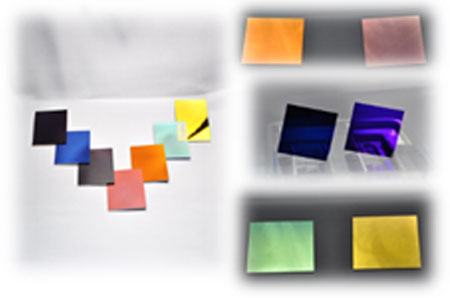

Decorative film

By forming a multilayer film by sputtering, it is possible in principle to create almost unlimited colors due to the light interference effect.

①The processing to 3D shape is possible

Films can be deposited not only on plate-shaped workpieces, but also on cylindrical, rod-shaped, and 3-dimensional objects.

② Various colors

We have a large number of targets, and color sputtering is possible by depositing not only Cr and Ti, but also oxides and nitrides. We also accept color consultation.

③Work material

Thermal damage to the workpiece is extremely small, and film formation is possible on resin products that are vulnerable to heat.

④Strong adhesion

Strong adhesion can be obtained not only to glass and metal, but also to resins such as PC, PET, PP, ABS, and ceramics.

*Acrylic plate Al + protective film (no hard coat)

Decoration example

Examples of decoration on cosmetic bottles

Examples of decorating sprockets (motorcycle drive parts)

Examples of decorating fishing gear (lures, harpoons)

Examples of decorating car accessories (emblems, exterior parts)

Examples of decorating beauty products (scissors)

Example of decorating a kitchen sink lever